The technology of double-sided 4D printing has been developed, which does not require the use of a hydrogel or human participation to change the shape of an object.

Four-dimensional printing is called ability3D objects made using a 3D printer reversibly change their shape in response to external factors such as heat or moisture. Previously, to return to the initial state, it was necessary to manually stretch or straighten the object, which could require considerable effort and time.

In recent years, scientists have been able to achieveauto shape change but this effectachieved through the use of hydrogel as a stimulant. The problem is that it has insufficient mechanical strength, so it greatly limits the use of manufactured objects. Other options using alternative materials made the reversibility process very slow.

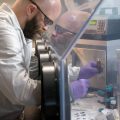

To solve these problems researchers fromSingapore University of Technology and Design, together with colleagues from Nanyang Technological University, used just two materials (the rigid VeroWhitePlus and the rubbery TangoBlackPlus) that are suitable for inkjet 3D printing and are able to maintain significant mechanical strength during and after they are put into action.

During testing, the team soaked the elastomerethanol, simulating the hydrogel swelling process, to cause a load on the transition material, which changes shape depending on temperature. After the evaporation of the alcohol, heating the transition material again restores its original shape, since the elastomer draws it back due to the energy of elastic deformation accumulated in it after drying.

The elastomer performs double duty, causingtension at the programming stage and storing energy in the material during recovery. At the same time, the process of returning to the original state turned out to be more accurate compared to other alignment methods.

Although this approach is still in its infancystage, but its further development could provide a wide range of applications with the spread of 3D printing in the future. It will allow the creation of complex structures that can be transformed under the influence of the environment. For example, smart curtains that automatically respond to heat levels throughout the day without any sensors or electronics.

We also previously reported on the development of a 4D printing system for making plastic rods that can bend, fold, and twist into specific shapes when exposed to heat.

text: Ilya Bauer, photo and video: YouTube / SUTD