Researchers have found that woody materials can be bent into shape by modeling their compression during drying.

Existing methods for manufacturing complex,Curved wood objects take up a lot of energy, and cutting or sanding unwanted parts creates a lot of waste. However, materials scientists from ETH Zurich and the University of Stuttgart have found a way to use wood's natural ability to absorb and release moisture to create similar structures.

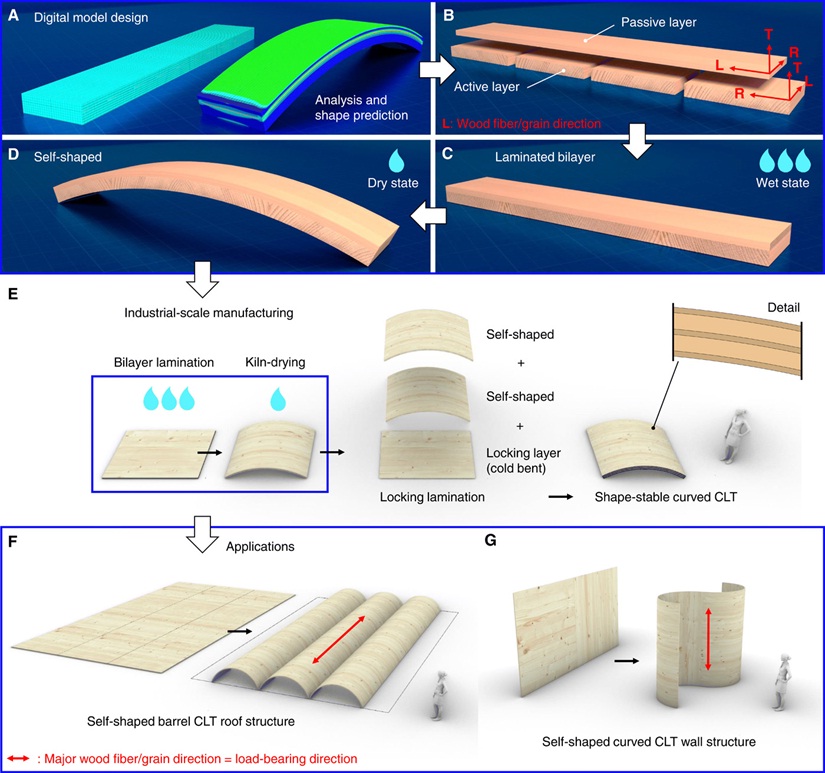

First, a team of scientists developed a computera model that allows you to predict the deformation of the board depending on the type of wood, natural moisture and the reaction to its changes. Then they figured out how to use the natural features of individual fragments to create complex structures of the desired shape without machining.

In order to test the effectiveness of the methodology in practice, they designed and built a 14-meter structure called the Urbach Tower.

When creating it they used two types"wet" wood: European beech and common spruce. By gluing individual thin elements together, the researchers made layered boards. As they dried, one layer was compressed, and the second – no, causing the entire board to bend without cracking. Once the desired shape was achieved, the pieces were held together to prevent further changes, and the bent boards were then used to construct the entire demonstration structure.

We also previously reported that engineers have found a way to make wood more than ten times stronger, creating an inexpensive and lightweight alternative to most metals and alloys.

</p>