Researchers have developed technology that improves the flexural strength and fracture toughness of silicon carbide by 50%.

Silicon carbide is promisingconstructional material for the manufacture of refractory parts. Nowadays, it is increasingly used in industry as a semiconductor, construction, refractory and abrasive material. For example, it is used to make turbine blades, ICE parts, and ceramics for the automotive industry.

The problem is that due to the highsensitivity of silicon carbide to structuraldefects, it often has low tensile strength, bending and crack resistance. However, scientists from the National Research Technological University MISiS have found a way to improve the sinterability of the material by forming reinforcing nanofibers in it.

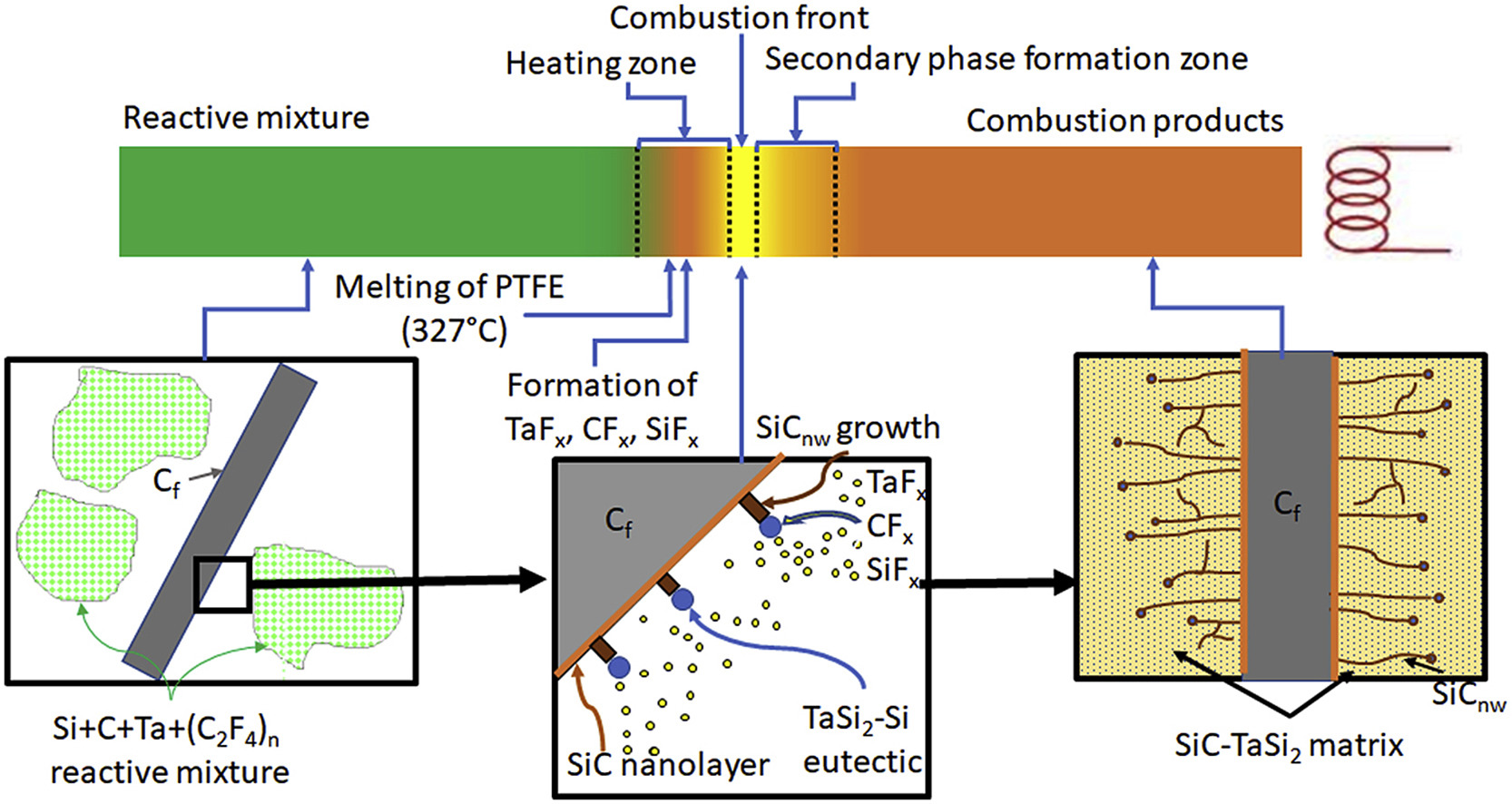

The team used technologyself-propagating high-temperature synthesis carried out in several stages. First, powders of silicon, carbon, tantalum and polytetrafluoroethylene were mixed in a planetary mill. Then the resulting mixture was burned in a reactor, where nanowires were formed in the process of combustion. At the last stage, the substance was sintered in a vacuum oven.

This made it possible to synthesize silicon carbide withreinforced matrix, increasing its bending strength and crack resistance by 1.5 times. In addition to improving the mechanical characteristics of the material, nanofibers reduce the required temperature and duration of sintering from several hours at 1800-2000 °C to 60 minutes at 1450 °C, reducing production costs and expanding the scope of application in aircraft manufacturing.

In addition to improving existingResearchers are also inventing new materials with amazing properties. We recently reported on the development of the world's first material that cannot be cut or drilled.

</p>