Researchers have developed a fast and cost-effective method for extracting precious and toxic metals from e-waste.

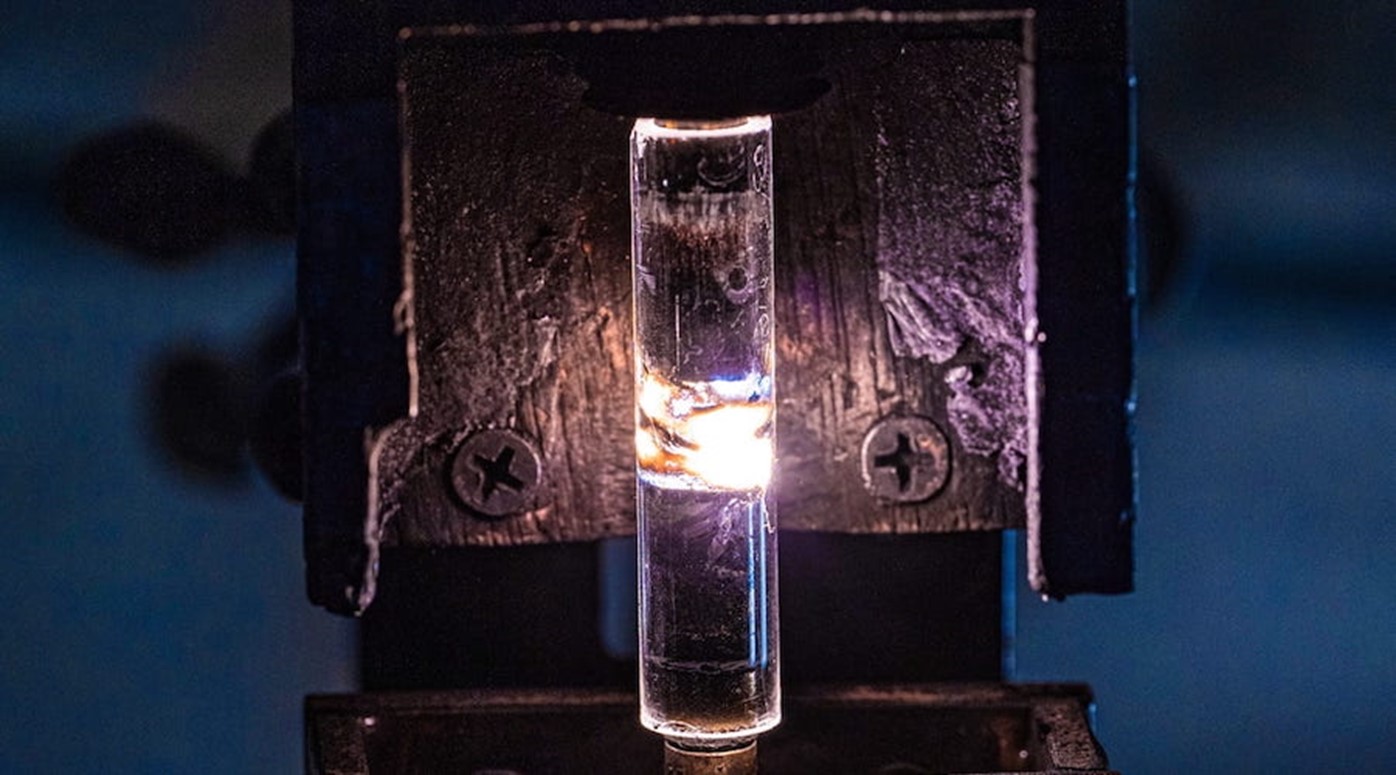

A method called Joule heatingused in many industrial processes and even for the production of graphene from food waste. It provides for an instant increase in the temperature of the object to 3400 K using an electric discharge. As a result of this action, the target material is separated, turning into a gas.

Now a team from Rice University has decided to adapt this method to electronicwaste.To do this, scientists first crushed the printed circuit boards and added halides (table salt and a little soot) to them in order to increase the yield of the target product. After the Joule flash, precious (rhodium, palladium, gold, silver) and toxic heavy metals (chromium, arsenic, cadmium, mercury, lead) evaporate.

Then the vapors are transferred from the evaporation chamber withusing a vacuum in another vessel, a cold trap, where they condense to form their constituent metals. The resulting mixture can be refined to single metals using well known refining techniques.

Experiments have shown that one instantThe Joule reaction reduces the lead concentration in the remaining char to below 0.05 ppm. According to the researchers, the scalable process consumes only about 939 kWh of energy per ton of material processed, which is 80 times lower than the consumption of commercial melting furnaces. It also eliminates the time-consuming cleanup required for smelting and leaching processes.

Previously, we also reported the first case of creating metallic water under terrestrial conditions.

</p>