The European Commission is funding the development of the first system to repair ship hulls using friction welding, which can work underwater and move independently on board.

The project called RESURGAM (Robotic Survey, Repair and Agile Manufacture) involves 13 organizations led by Forth.

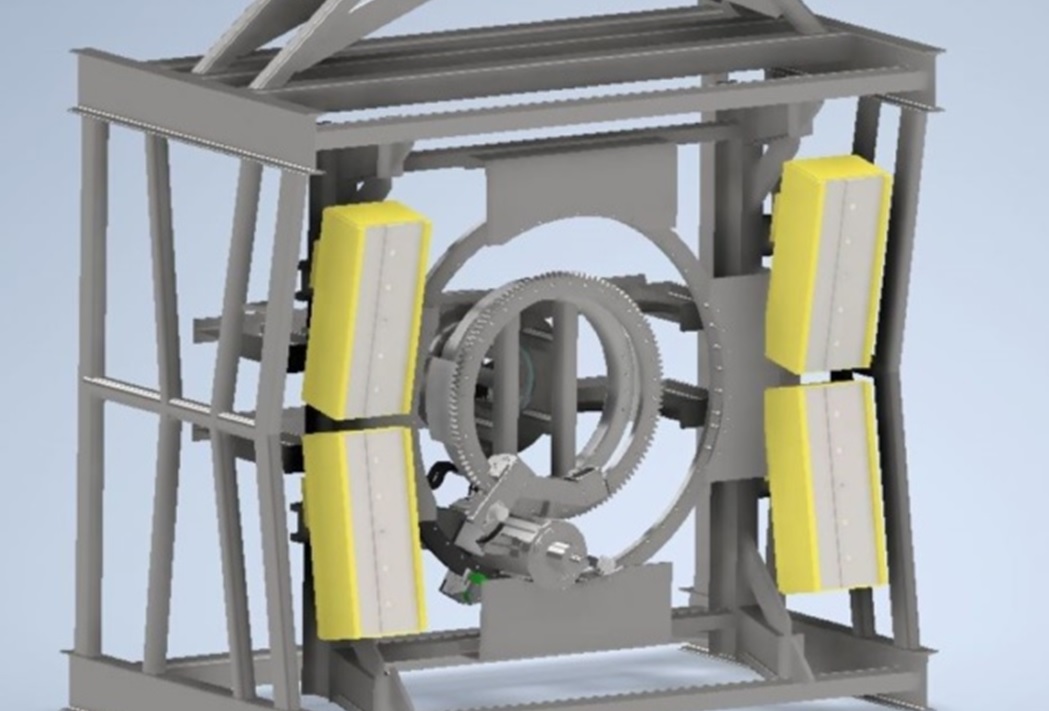

The robot being developed will consist of a weldinghead and a mechanical frame mounted on the side of the ship's hull. The device will be attached using four R1000 electromagnets, each of which is capable ofcreate an attractive force of 7.5 t, providing the necessary force along the Z axis for welding.

The system will be able to move on its ownvertical plane between the repair patch and the defective section of the hull. This will allow specialists to repair the ship directly at sea without the need to go to dry dock, controlling the process remotely from anywhere in the world.

The technology will not only help save time and money, but will also make repairs safer for humans by eliminating the need for divers.

Engineers are currently working on detaileddesign of RESURGAM structural elements and control program. After creating a fully functional sample, it will be tested in the British specialized complex Deep Test Pond.

Let us recall that previously acoustic Wi-Fi was also tested for wireless data transmission underwater over long distances.

</p>