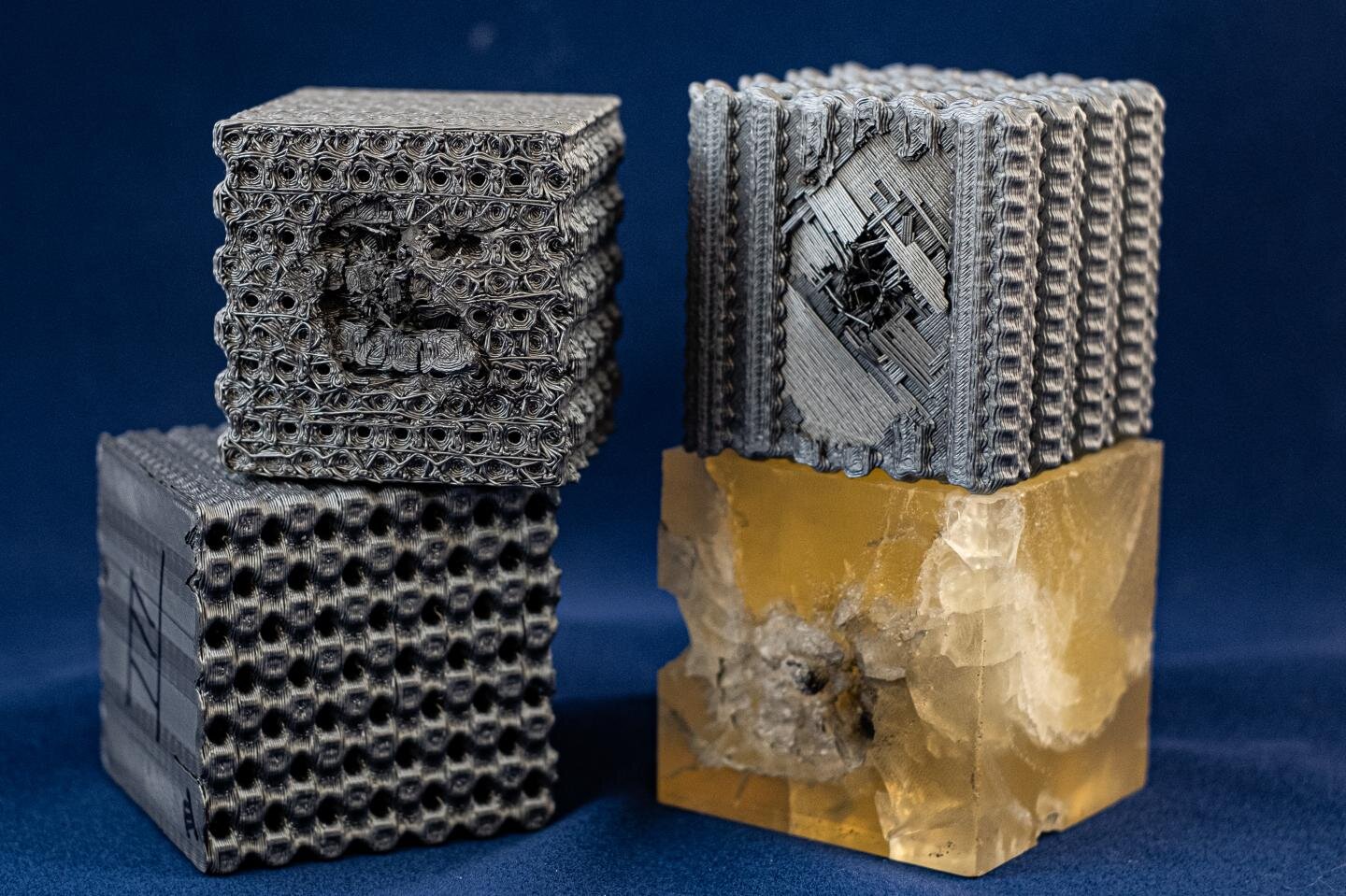

Small bullet dents are a clear proof of the strength of lightweight porous polymer blocks made using a 3D printer.

Materials scientists from Rice University studiedpolymers made from carbon nanotubes (tubulans), which are expected to have extraordinary strength. However, these structures are still theoretical and scientists have yet to learn how to create them. Therefore, to test the developed computer models, the team decided to use available materials.

In the process of research, scientistsdetermined that tubulans can be imitated asscalable blocks of polymer tubes created using three-dimensional printing. To test the developed models, the team fired shells at different types of cubes at a speed of 5.8 km / s.

Experiments have shown that light porousstructures stop bullets 10 times better than solid blocks of the same material, and a polymer lattice prevents cracking during failure.

According to scientists, such structures canmade of plastic, metal, ceramics, and their size is limited only by the capabilities of a 3D printer. Topology optimization will improve the materials used in industry, aerospace and automotive industries, civil engineering, sports, and biomedicine.

Previously, we also reported on the creation of the blackest material to date, absorbing 99.96% of light.

text: Ilya Bauer, photo and video: Rice University